Showing posts with label Chandler and Price. Show all posts

Showing posts with label Chandler and Price. Show all posts

Friday, September 5, 2008

Roller crisis averted!

When I bought my C&P, the lower saddles (which hold the third roller) were stuffed with cotton. The inside surfaces of the saddles were dramatically worn, and I guessed the cotton was a makeshift way of keeping the rollers in place and preventing further wear.

The left saddle (pictured above) was bad, but this one was even worse...

When I posted the photos on Briar Press as a kind of "uh oh... what do I do now?" I got some pretty alarming responses from the experts, including:

"The saddle on the one side seems so thin the end looks like it’s about ready to break off. If that happens when the press is running and the roller get smashed between the platen and the bed it could destroy the press."

and...

"That one looks mighty shaky to me and I’d be worried about it breaking and the roller coming loose. The roller springs are pretty strong and exert a lot of force pulling the rollers down. If one end breaks while the press is running I can imagine the roller flying toward the operator or dropping into a closing press. Neither is very desirable. I’d look into finding replacement roller saddles or having a machinist repair the existing ones by welding or brazing in some new metal."

Since I definitely didn't want a roller-flinging, head-injury-inducing, press-destroying disaster on my hands, I decided to deal with the saddles straight away.

Suggestions for having a machinist repair the roller saddles or simply removing the lower roller and printing on just two rollers for a time (which is possible on a Chandler & Price) were fine, but I really wanted to be done with the problem sooner rather than later. I'm ready to have this press in perfect shape. So I posted a Want Ad on Briar Press (bless Briar Press!) and after just one week I'm the proud almost-owner of these good-as-new single roller saddles and springs.

And – bonus! Paul, who's selling me the saddles, is also selling me a bail! You can see the edge of it at the top left of the photo. My press came without a lower bail... whoever used it last had been improvising by fixing the tympan to the underside of the platen with lots of tape. We removed oh-so-many layers of tape. The replacement we had fabricated at a machine shop doesn't fit tight enough in the right places, causing the tympan and packing to bulge and shift – not good!

So it looks like we're solving the very last of the problems. Exciting times...

Monday, August 25, 2008

Even older

Thanks to Arie on Briar Press, I've discovered my Chandler & Price is even older than we thought.

According to this list my Old Style press, with a serial # of 38489, was built in 1902. I had previously (and incorrectly) dated it at 1904 by looking at a different, less accurate list.

It's 106 years old! What a life. I know it's seen Ohio (where it was built), Minnesota (to undergo a factory rebuild by Brandtjen & Kluge), Washington state (where I bought it) and has travelled through a whoooole lot of states on the way to Mississippi, where it lives with us now.

I can't help wondering about all the fascinating places I don't know it's been...

...

According to this list my Old Style press, with a serial # of 38489, was built in 1902. I had previously (and incorrectly) dated it at 1904 by looking at a different, less accurate list.

It's 106 years old! What a life. I know it's seen Ohio (where it was built), Minnesota (to undergo a factory rebuild by Brandtjen & Kluge), Washington state (where I bought it) and has travelled through a whoooole lot of states on the way to Mississippi, where it lives with us now.

I can't help wondering about all the fascinating places I don't know it's been...

...

Monday, February 11, 2008

Letterpress: Evolution

Above: my 1902 Chandler & Price Old Style 8x12 letterpress "in the wild" in a little town outside Yakima, Washington, when I bought it on April 28 last year. Even before it got outside (it was only in the elements for about a week) it had accumulated a substantial coat of dirt, oil and grime, and was showing its age.

Ten months and 4000-odd miles later, the letterpress emerges from climate-controlled storage and undergoes the "Dad treatment". My dad used 'down time' during his visit from Australia to whip the press into shape: new motor, new pulley, new belt, gear rebuild, comprehensive oiling, and more cleaning than it had probably seen in decades. The photo above shows it without its upper feed table (which tends to obscure some of the work). The photo below shows what it looked like before Dad came along.

See? It was a bit scary. And deeply dirty.

See? It was a bit scary. And deeply dirty.The picture below shows the press after Nathan's Dad got going on it last week. Among other things, he cleaned and shined the ink disk, fitted a kill switch (which my Dad lamented not having time to do before he left) and attached the upper feed table after a minor repair.

You'll notice two of the three rollers are missing in the photo above. The previous owner had apparently been getting by on two rollers, but I've ordered three new vinylith rollers from NA Graphics in Colorado, along with trucks, California wash, tympan and packing.

You'll notice two of the three rollers are missing in the photo above. The previous owner had apparently been getting by on two rollers, but I've ordered three new vinylith rollers from NA Graphics in Colorado, along with trucks, California wash, tympan and packing. Above: another "before" photo, showing years of accumulated grime.

Above: another "before" photo, showing years of accumulated grime. Now that's better... lots of olive oil, fine-grade steel wool, 3-in-1, marine grease, compressed air, fine-grade sandpaper, kerosene, WD-40, and two Dads later – I have a letterpress to be proud of.

Now that's better... lots of olive oil, fine-grade steel wool, 3-in-1, marine grease, compressed air, fine-grade sandpaper, kerosene, WD-40, and two Dads later – I have a letterpress to be proud of. I still need to order grippers (just last week I realised they were missing, not just packed elsewhere) and a new bail to replace one that looks like it broke off years ago... but I'm getting scarily close to having no excuses not to use this monster! It's exciting and daunting.

I still need to order grippers (just last week I realised they were missing, not just packed elsewhere) and a new bail to replace one that looks like it broke off years ago... but I'm getting scarily close to having no excuses not to use this monster! It's exciting and daunting.But mostly exciting.

.

Wednesday, January 30, 2008

Cleaning a letterpress

I was told that to clean an old letterpress, you need fine-grade steel wool, drill bits of various sizes, a bristle brush, 3-in-1, WD-40, kerosene, 30-weight oil and old rags.

I've discovered the other things you need: a whole lot of time, and a Dad.

I took a good stab at the first stages, although getting around the machine can be a bit tricky now I'm most of the way through my second trimester.

First I brushed at least a decade's worth of dirt and grit off the machine with a pan brush. Then I did it again. It was particularly stubborn dirt because it was "glued" in place with all the oil that's required to run the press and keep it from rusting.

Next: the air compressor. When Nathan and his dad bought that noisy monster I thought there was no way I'd ever need it. I was wrong. It's fabulous for blasting dirt and grime out of places that can't be reached with a brush. I went over the press a couple of times with that and was pretty pleased.

Then I started hunting out the oil holes. Letterpresses have more oil holes than you can poke a stick at, and before you can run one that's been idle for a while, you have to find all the holes (many of which are in mysterious and inaccessible places), clean them out with a drill bit and a Q-tip, and then put in a couple of drops of 3-in-1. It's a long process.

I was partway through the oil-hole mission when Mum and Dad arrived from Australia. If I'd known what a letterpress-restoring powerhouse my Dad could be, I might've been tempted to let him handle the whole job.

Actually, he did. We made a couple of runs to Home Depot and Lowes to get extra supplies Dad knew we'd need, and then he went to work.

I wouldn't let just anyone take a stab at fixing the letterpress. It's more than a century old, huge, heavy and dangerous – and despite its bulk it can be ruined. But Dad's spent the best part of his life restoring vintage cars to their former glory. He really knows his way around expensive and complicated old machines.

Well, Dad took over the letterpress corner and was basically unstoppable. One day when I have more time and memory-power, I'll try to make a list of the countless things he did. For now, I'll just go with the old picture's-worth- a-thousand-words... when Dad arrived, the letterpress looked like that (see picture above). Even before he was finished with it, it looked like this (below).

And it worked.

Sunday, January 6, 2008

The Letterpress Saga: Part Four

It wasn't as hair-raising this time.

On New Year's Day, Nathan suddenly decided it was time to get my century-old Chandler & Price Old Style platen press out of storage, where it's been snoozing in climate-controlled comfort since our move from Seattle, and into our garage.

He called a few tow-truck/wrecker companies before he found a guy willing to tackle the job. We learned from bitter (and terrifying) experience that you need a forklift or a tow truck to get this monster from one level to another. We've also learned not to tackle it alone.

This time Nathan and John-the-tow-truck-guy used a pallet jack to get it on the back of the truck and used ratchet straps to tie it ten ways to the bed. Then we held our breath all the way from D'Iberville to our house, with Nathan saying helpful things like "It's gonna come off this corner for sure" and "There it goes".

At home, they strapped the press base to the pallet jack, raised the bed and used the winch to inch the press down to the garage. I was holding my breath, but not having conniptions like last time.

It's now safe and sound in my soon-to-be letterpress workshop in the back half of our garage, ready for its grand makeover. There's a lot of work ahead involving drill bits, oil holes, 3-in-1, fine-grade steel wool and WD-40, and no doubt some silent swearing.

It'll be worth it though. I've dreamed of this forever.

Monday, June 18, 2007

Moving a letterpress... again

My marvellous old Chandler & Price letterpress is on the move again, and this time we learned from our mistakes! Last time was very nearly a disaster...

We hired a tow-truck guy to lift it straight into the Penske (he looked skeptical when he saw it, but everything worked fine) and 3000-odd miles later, Nathan and Dad backed the truck up to a raised storage unit and used the pallet jack to wheel it right in. So: no 3am terrors and no endless physics questions.

Much better!

.

Labels:

Chandler and Price,

letterpress,

moving,

moving a letterpress

Sunday, May 6, 2007

The Letterpress Saga, Part Three

If you ask me, a forklift is the very best way to move a letterpress. We learned that the hard way.

Steve used one to move my new (oh-so-old) Chandler & Price platen from his letterpress wonderland into the back of the Penske for the big haul across the Cascades. It was beautifully simple; the easiest possible way to do it.

See? The easiest thing ever... assuming you can operate a forklift...

The trouble began when we finally got the truck home around 10.30 on Sunday night. We were worn out and looking forward to getting the letterpress move over with – long day, lots to get done, and soooo much driving. Instead, we spent the next four hours in a slow-motion nightmare that seemed destined to end with the complete destruction of my beautiful century-old letterpress.

(I told you there was drama.)

The Penske truck has a lift on the back, touted as a good thing for safely lowering a letterpress – no doubt by someone who's never laid eyes on a letterpress. But when we get the lift going, we discover it sits at an alarming downward angle. Maybe an angle of 5 degrees – maaaaaybe – but any angle at all is alarming when you're moving a letterpress.

Our friend and neighbour Mike comes over to help us – a move he'll regret for years. But thank goodness for Mike. First of all, before becoming a doctor Mike was an Air Force engineer (and evidently a sucker for intellectual rigor) and an engineering consultation is definitely needed for this job! Second of all, we need at least three people working against the letterpress, which for four long hours seems determined to hurl itself onto the concrete from a height.

Nathan and Mike spend the next four hours discussing, planning, strategising, inching the letterpress around on the pallet jack, testing the lift, and throwing around worrying phrases littered with "top-heavy" and "torque" and other words I don't want to hear. I look after Berry inside and tell myself I can't look I can't look, and then I pray pray pray, and then I peek through the blinds obsessively at five-minute intervals, then I go outside to "help" (fret) as often as Berry will tolerate (thank goodness for The Wiggles). Every attempt to get the pallet jack with the letterpress out onto the lift is disastrous. The letterpress is incredibly heavy, uneven, unstable, top heavy, and unstoppable once in motion – basically everything you don't want in a fragile piece of equipment that you're trying to move. On the first attempt, the press actually teeters on the edge of toppling over the lift and on to the ground. I swear. I'm not a fainting girl but I could pass out. Like Steve says, one slip and it's scrap metal.

Eventually (because boy oh boy is this story long in real life) Mike decides it can't be done. Not really, not safely, not without the very distinct possibility of smashing 1000lbs of metal and 100 years of history on to the floor of our carport. I can't bear the thought. But Nathan, having come this far, isn't backing down. He and his pallet jack are getting this letterpress down, come hell or high water. I'm beside myself.

A lot more strategizing. Even more alarmingly, every single one of these strategies ends this way: "And if it goes, it goes. Everyone duck." The common theme is the demise of my treasured press.

Marianne (who along with Mike must be sainted, pronto) gets out of bed at 1.30am to babysit Berry while the other three of us start putting our marginally-least-foolhardy plan into action. We lock the lift up, manouevre the letterpress on the pallet jack to the inside (truck) edge of the lift, attach ratchet straps from the top of each side of the flywheel back into the bars on each side of the inside of the truck (confused yet?) and then try to inch the pallet jack out on to the lift. Mike and I hold tension on the ratchet straps and Nathan moves the press forward, inch by eternal inch. We keep running into trouble. The press won't go over the lip between the truck and the lift – not without using rocking and momentum – and momentum is the enemy of the letterpress move.

We get it past the first lip (stuffed with cardboard) and then the second lip becomes a problem and refuses to be stuffed. It's dark and cold and we can't see what we're doing, and the press is heavy against the ratchet straps. We stop constantly for Nathan to measure how much further we need to go, to get the pallet jack all the way out onto the narrow lift. It's crucial that we don't go any further out than we have to, because the lift is terribly narrow and the downward angle becomes more alarming with every inch. The press wants, very much, to rock forward on the lift and slide over the edge.

Our plan is, when the pallet jack gets all the way out on to the lift, the lift will dip downwards and the press will start to pull forward toward the ground – hard. Mike and I will pull back on the ratchet straps, attached to the flywheel at the front end, as hard as we can, while Nathan jumps down and lowers the lift. I keep asking, How will I know when to pull? and they say, You'll know.

In the end, we're all pulling straps and switching places, and I'm not even sure who lowers the lift – only that there's a heart-stopping moment where the lift goes up instead of down, and that when the letterpress reaches the ground intact, we nearly collapse with relief.

Oh my, it's a letterpress miracle!

Things to come out of this experience:

1) moving a letterpress is not for the faint-hearted, easily tired or weak-armed

2) trucks with automatic lifts are not as useful as they sound

3) our neighbours deserve champagne and medals

4) go get you a forklift

And of course, the biggest thing to come out of this experience... a whole new shiny- magical- new world of letterpress to explore. I can't believe my luck.

Oh yeah... we're moving again in four weeks. Anyone got a forklift?

:(

Wednesday, May 2, 2007

My press

This is my century-old Chandler & Price platen press "in the wild", if you will... right before we loaded it into the truck.

I'm looking forward to returning it to its former glory – or at least getting it close.

The Letterpress Saga: Part Two

When we arrived at Steve's place, in a tiny town on the other side of the Cascades, we found a letterpress wonderland. Seriously, he has everything – a Chandler & Price Old Style like mine, another larger letterpress, an incredible linotype machine (about 1886), a Rosback punching machine and an impossible-to-find Rosback Pony Six, just to name a few.

He's been collecting all these amazing old machines from all up and down the West Coast, saving them from disrepair – or, worse, destruction at the hands of scrap metal merchants.

He has an entire workshop/studio set up as a traditional print shop, and it's stunning. I got a tour of the whole place and learned so much – and that was before the letterpress lesson.

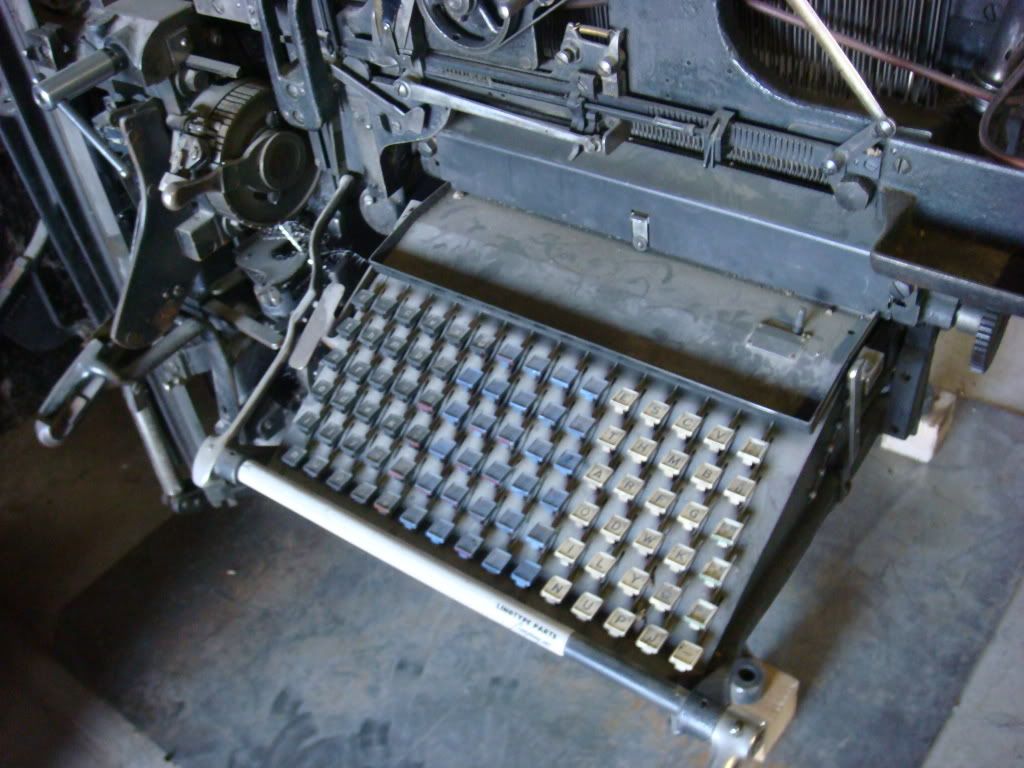

This (above and below) is the linotype machine, which Thomas Edison described as "the eighth wonder of the world". Introduced in 1886, it revolutionised the printing industry by allowing printers to set a complete line of type using the Linotype's 90-character keyboard (below). Previously, they had to set movable type by hand – one... letter... at... a... time...

This (below) is Steve operating his C & P Old Style – it's just like mine except it has a treadle. And of course, is currently much, much cleaner! My next time-consuming job will be cleaning every inch of this monster, making it immaculate and ready to run...

I got enough stuff from Steve – furniture, leads, quoins, paper, ink, quads, chases – to last a lifetime! Also a composing stick, a stone, a furniture cabinet, type cases, a key, two planers and a line gauge.

Next episode: the exciting stuff. The hours in which we do not know whether the letterpress will see the morning...

Tuesday, May 1, 2007

The Letterpress Saga: Part One

The Letterpress Saga started, of course, with me deciding I needed a letterpress.

I've wanted one for years – ever since I knew what a letterpress was. I was always picking up letterpressed stationery and imagining how I could do this. But I'd heard so much about the expense and complication involved in finding, running and maintaining a letterpress, and none of it seemed very practical.

Then I watched a short documentary by Chuck Kraemer about traditional letterpress at Firefly Press, Massachusetts, and it tipped me over the edge. I had to have one.

After a lot of lurking around Briar Press and bombarding a very helpful soul named Kevin with some fairly green questions, I found the perfect press for me. A century-old Chandler & Price Old Style 8x12, located in central Washington... on the other side of the Cascades, but manageable because it was accessible and on the level.

See, the thing about getting a letterpress is not so much whether you can find one, but whether you can move the monster once you do. They are huge. They are unwieldy. They are unbalanced, and they are extremely heavy. And in the words of Steve, the great guy I bought my press from: "one slip and it's scrap metal".

So if you're trying to get one out of a basement, or up or down stairs, or out of a tight space of any kind, you have a fight on your hands. And the letterpress may well win.

We were lucky because my C&P was on level ground, in wide-open space, being capably cared for by Steve, a super-motivated letterpress rescuer and collector. He promised me a detailed letterpress lesson, a tour of his fully equipped letterpress workshop, and as much gear as I could carry home. So we took rented a big truck with a lift and lots of ratchet straps and drove three hours across the Cascades.

Yeah, this is a long story. To be continued....

Subscribe to:

Posts (Atom)